Abstract

Chem Safety Data Sheets (SDS) are the unsung heroes of the chemical industry, and compliance tools are the unsung heroes of SDS. I’ve spent over a decade navigating this complex world, and I’ve seen firsthand how understanding and properly using SDS can make a huge difference—both legally and operationally. This article blends my personal journey with practical insights, covering the evolution from MSDS to SDS, the challenges of compliance, and the tools that have helped me and others thrive. Through real stories and hard-earned lessons, I aim to provide a guide that not only informs but also inspires others to take chemical safety seriously.

Table of Contents

- The Importance of Chem Safety Data Sheets

- Challenges and Solutions in Compliance

- A Personal Journey with SDS

- Essential Compliance Tools

- The Future of Chemical Safety

The Importance of Chem Safety Data Sheets

Let me start with a story. Years ago, I was auditing a small chemical distributor, and their SDS collection was a disaster. Half were MSDS—old, inconsistent, and nearly impossible to decipher. The other half were photocopies of photocopies, riddled with errors. It was a nightmare. But here’s what stuck with me: when I asked their safety manager why they hadn’t updated, they shrugged. “It’s just paperwork,” they said. That’s when I knew I had a job to do.

SDS aren’t just bureaucratic hoops to jump through. They’re the frontline of chemical safety. Without them, how do you know if a chemical is flammable, corrosive, or toxic? How do you train employees, respond to emergencies, or comply with regulations? I’ve seen companies fail because they didn’t have access to accurate SDS. It’s a real problem, and it’s why I’m passionate about promoting the use of SDS and compliance tools.

The transition from MSDS to SDS was a game-changer. The Globally Harmonized System (GHS) standardized the format, making it easier for everyone to understand. But the real value comes from the information inside. Take, for example, a hypothetical chemical like 2-Chloroethylamine. Its SDS would detail hazards like skin irritation, respiratory issues, and environmental toxicity. It would also provide first-aid measures, firefighting instructions, and safe handling procedures. This information can be lifesaving in an emergency.

| Section | Content |

|---|---|

| Section 2: Hazard Identification | Classifications, signal words, hazard statements |

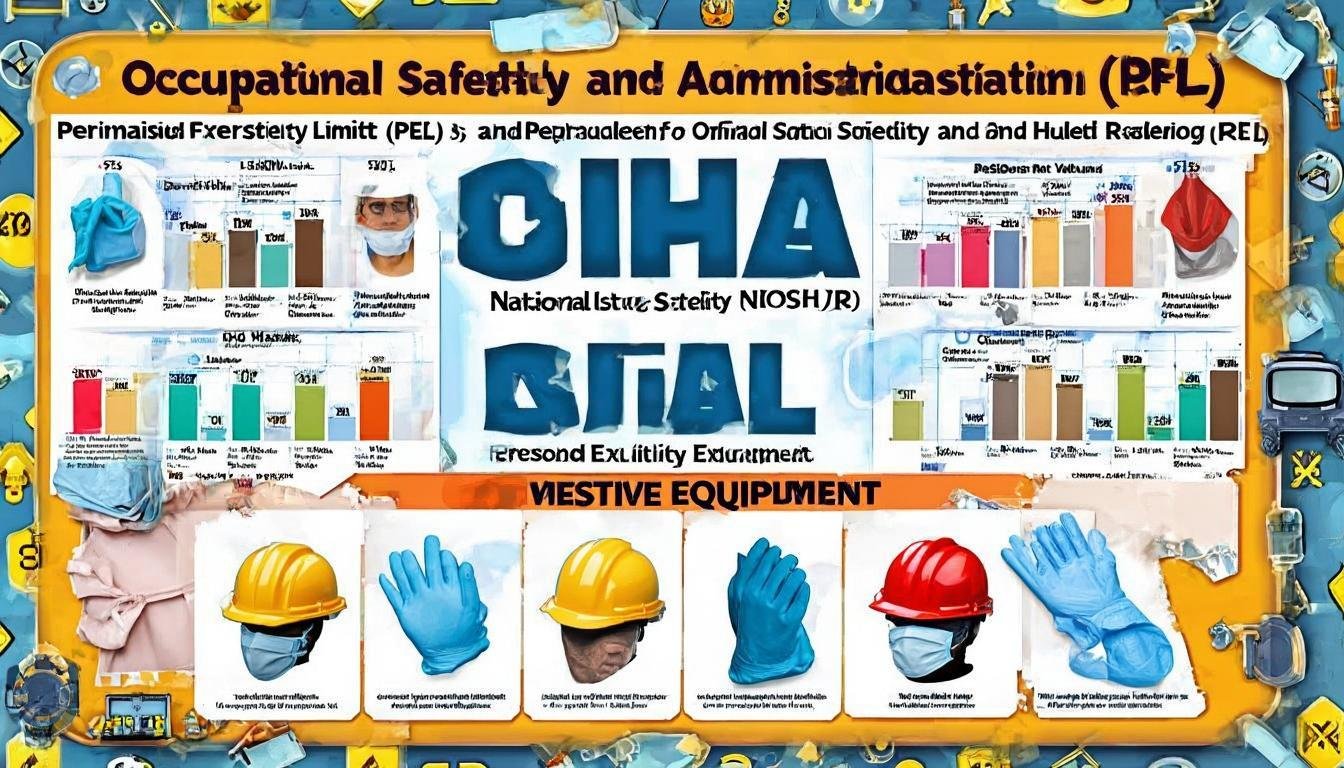

| Section 8: Exposure Controls/Personal Protection | OSHA PEL, NIOSH REL, personal protective equipment (PPE) |

| Section 13: Disposal Considerations | Waste disposal methods, regulatory guidelines |

Standardization is key, but the real challenge lies in keeping the information accurate and up-to-date. Outdated SDS can be just as dangerous as having no SDS at all.

Challenges and Solutions in Compliance

Compliance with chemical safety regulations is no walk in the park. I’ve faced my fair share of hurdles, and I’m sure many of you have too. One of the biggest challenges is keeping up with changing regulations. The transition from MSDS to SDS, for instance, required a massive effort to update existing documents and train employees. It was a headache, but it was necessary.

Another challenge is the sheer amount of information that needs to be managed. SDS can be long and detailed documents, and it’s easy to get overwhelmed. That’s why having the right tools is so important. I’ve found that using specialized software can make the process much smoother. These tools can help you organize SDS, track changes, and even generate new ones.

A solution that has worked well for me is to create a centralized database for all SDS. This makes it easy to access the information you need quickly. Another tip is to regularly review and update your SDS. This ensures that you always have the most current information. Remember, outdated SDS can be just as dangerous as having no SDS at all.

The legal implications of non-compliance are severe. Fines can run into the millions, and in extreme cases, companies can face criminal charges. But beyond the financial penalties, there’s the ethical responsibility. How would you feel if a preventable accident occurred because your SDS were incomplete or incorrect? That’s why I believe in taking chemical safety seriously.

A Personal Journey with SDS

A few years ago, I was working with a small company that was struggling to comply with chemical safety regulations. They didn’t have a proper system in place, and their SDS were outdated. It was a mess, and I could see it was causing a lot of stress for everyone involved.

I decided to help them out. I spent weeks reviewing their chemicals, updating their SDS, and training their staff. It was a lot of work, but it was worth it. Within a few months, they were able to get their compliance in order. The difference was remarkable. They were able to operate more safely and efficiently, and their employees felt more confident in their work.

This experience taught me a lot about the power of SDS. It’s not just about following rules; it’s about creating a culture of safety. When you take the time to understand and use SDS properly, you can make a real difference. It’s one of the things I’m most proud of in my career.

I also remember a near-miss where understanding an SDS saved the day. A colleague was preparing to mix two chemicals, and the SDS warned against their reaction. He double-checked, and sure enough, the chemicals were incompatible. That’s the power of SDS—preventing incidents before they happen.

Essential Compliance Tools

When it comes to managing Chem Safety Data Sheets, having the right tools is essential. I’ve tried out many different compliance tools over the years, and I’ve found a few that stand out. One of the most useful tools is a chemical safety software platform. These platforms can help you create, manage, and update SDS efficiently.

Another great tool is a database for tracking chemical hazards. This can be especially useful if you work with a lot of different chemicals. It allows you to quickly find the information you need and ensures that you’re always up to date. I also recommend using templates for creating new SDS. This can save a lot of time and effort, especially if you’re new to the process.

Here’s a quick comparison of some popular compliance tools:

| Tool Name | Features | Price |

|---|---|---|

| ChemSafety Pro | SDS creation, tracking, and reporting | $500/year |

| ComplyEase | Chemical inventory, hazard tracking, SDS management | $300/year |

| SafeChem | SDS templates, compliance checklists, training modules | $400/year |

Each tool has its strengths, so it’s worth trying out a few to see which one works best for you. The key is to find a tool that fits your specific needs and helps you stay compliant.

The Future of Chemical Safety

Looking ahead, the future of chemical safety seems bright. With advancements in technology, we have more tools and resources than ever before. I’m excited about the potential of AI and machine learning to further improve chemical safety. For example, AI could help us predict and prevent chemical incidents more effectively.

Another trend that I’m excited about is the increasing focus on sustainability. More and more companies are looking for ways to reduce their environmental impact, and chemical safety plays a big role in this. I believe that by using SDS and compliance tools effectively, we can create a safer and more sustainable future for everyone.

As a consultant, I’m committed to sharing my knowledge and helping others navigate the complexities of chemical safety. I encourage everyone to stay informed and to use the tools available to them. Together, we can make a difference. If you have any questions or need further assistance, feel free to reach out. You can email me at boss@zofaith.com or call me at (86) 15725163518. Let’s work together to create a safer chemical industry.

Chem Safety Data Sheets & Compliance Tools are not just about regulations; they’re about protecting people and the planet. Let’s continue to prioritize safety and make a positive impact.